Orthodontic clear aligner treatment is experiencing considerable growth worldwide. This rising demand automation in the process chain for dental aligner production.

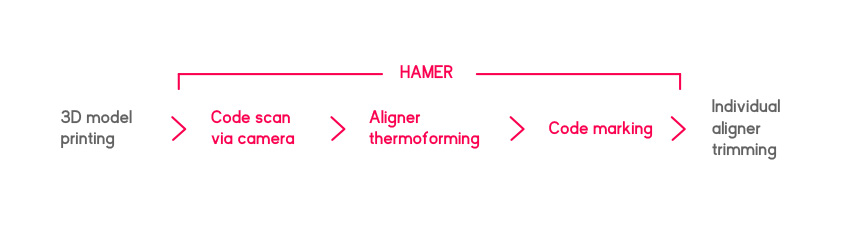

Production process:

One of the essential parts of the process is thermoforming. Dental thermoforming machines work by applying heat and pressure to a plastic sheet which is positioned on top of the 3D model printed specifically for that customer.

Professionals in the sector may find some challenges to achieve a well-defined aligner, to use different plastic materials, to increase production or to improve traceability.

After analysing all these constraints faced by aligner producers and taking advantage of our more than 40 years of experience in thermoforming and blister machinery, Hamer has launched a new automatic system for in-line thermoforming of dental aligners in which we offer the possibility of integrating vision and laser marking systems.

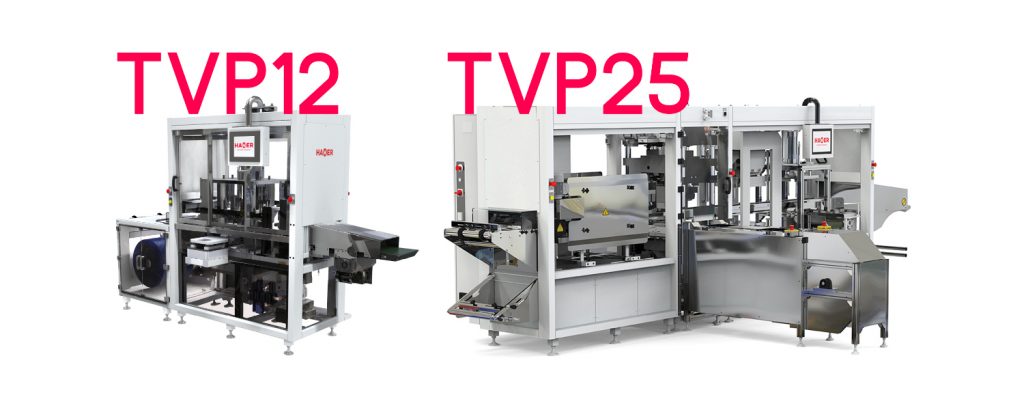

Within this new dental line, we offer two different solutions with several configurations available on each of them: TVP12 automatic line for medium productions and TVP25 for large productions.

These lines allow thermoforming between 100 and 1,300 aligners/hour.

This innovation offers many advantages for manufacturers of dental aligners compared to manual forming machines, among them, it is worth mentioning:

- Material cost savings of up to 50% by replacing the pre-cut sheet with film roll.

- Allows the use of different types and thicknesses of film.

- Thermoforming of the aligner at 10 bar pressure, which allows for improved definition of the aligner.

- Machine handled by a single operator.

- Possible integration of additional systems such as vision cameras for code reading, laser markers or cutting machines.

Learn more about the machines here.