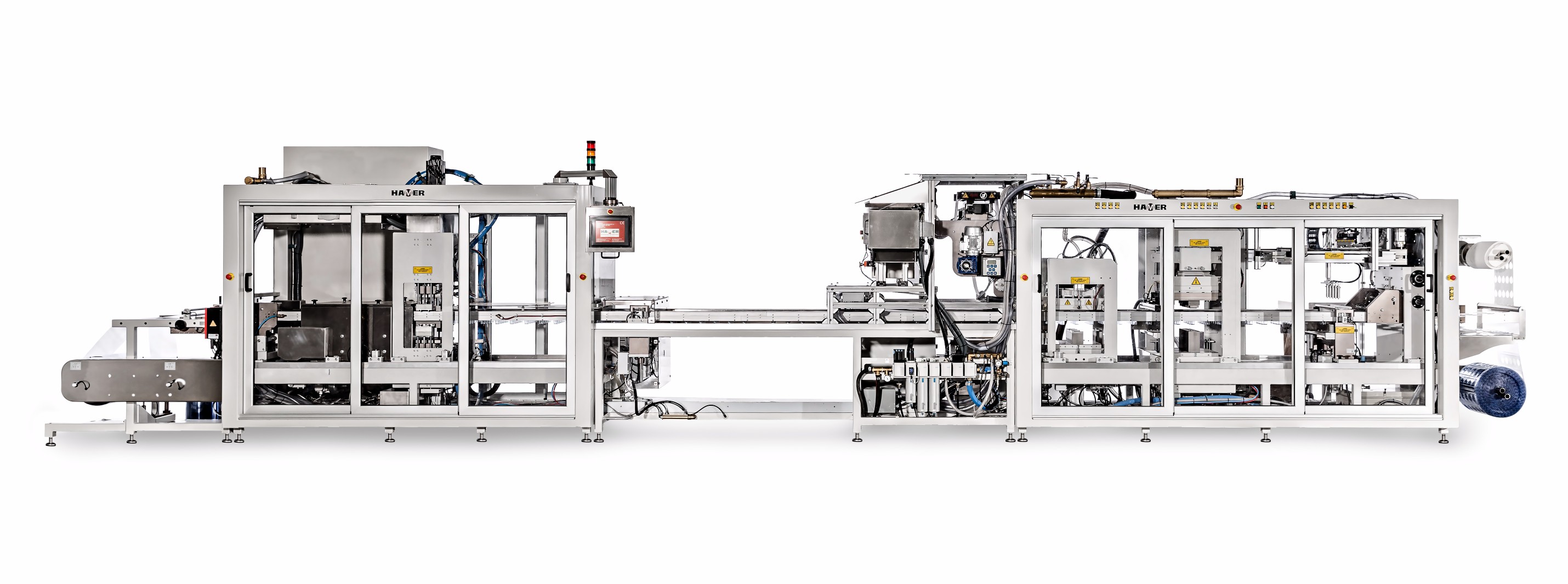

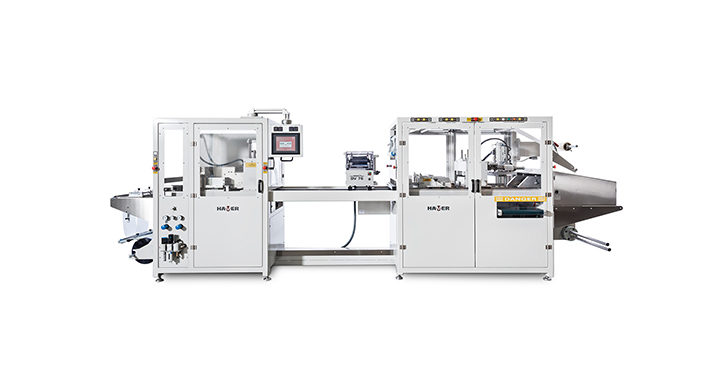

Automatic online machine suitable for packaging in rigid blisters of medical devices and their subsequent sterilization.

Features

Automatic online machine suitable for packaging in rigid blisters of medical devices and their subsequent sterilization.

- Dedicated to the production of medium and long runs.

- Modular design through available options.

- Robust and accessible construction.

- Low operating and maintenance cost of the machine.

- Quick tool set change-over.

- Pressure forming that allows the molding of film up to 0.8mm thick with precise molding.

- PLC operated, touch-screen controlled.

- Steel-rule die cutter, which avoids misalignment in the cut.

- Film traction by chain conveyor.

- Available in two sizes:

-

- 350×250 mm in the case of the BPC25M.

- 500×350 mm in the case of the BPC35M.

- Suitable for clean rooms.

- Guarantees the packaging of medical products in accordance with GMP regulations.

- Validable in accordance with existing medical regulations.

- EU safety rules compliance

The most common optional extras are:

- Customizable length of loading area.

- Dedicated printing and coding system (flexographic printers, inkjet based coders, etc)

- Automatic card feeder.

- Punching station for the euro-holder.

- Possibility to manufacture Blister to blister pack.

Operation

The BPC25M / BPC35M Medical integrates all the necessary operations for the manufacture of the blister according to the specifications necessary for clean rooms and validable according to specifications. The operations range from the thermoforming of the bubble from a roll, through the loading area, to the operations of sealing, individual punching of each of the figures and ejection of the finished blister.

Dimensions approx. (H x W x D)

2.500 mm x 1.500 mm x 11.000 mm

Estimated weight

6.000 kg

Roll diameter forming material (max.)

500 mm

Maximum thickness of forming material

0,8 mm

Forming material width (max.)

400 mm

Forming material width (min.)

260 mm

Forming area (max.)

350 x 250 mm

Forming area (min.)

200 x 100 mm

Height of forming below film level

80 mm

Forming pressure

6 bars

Capacity of vacuum pump

40 m3/h

Length of loading area

1500 mm

Height of loading area

950 mm

Roll diameter of lidding material (max.)

400 mm

Heated installed power

21,4 kW

Closing force sealing press (max.)

6.500 kg

Closing force trimming press (max.)

26.000 kg

Speed dry cycle (max.)

20 cycles/minuto

Total installed power

50 kW

Air consumption (at 20 cycles)

220 m3/h

Power supply

400V+N+G, 50 Hz

Application sectors

- Pharma

- Medical devices

- Medical implants