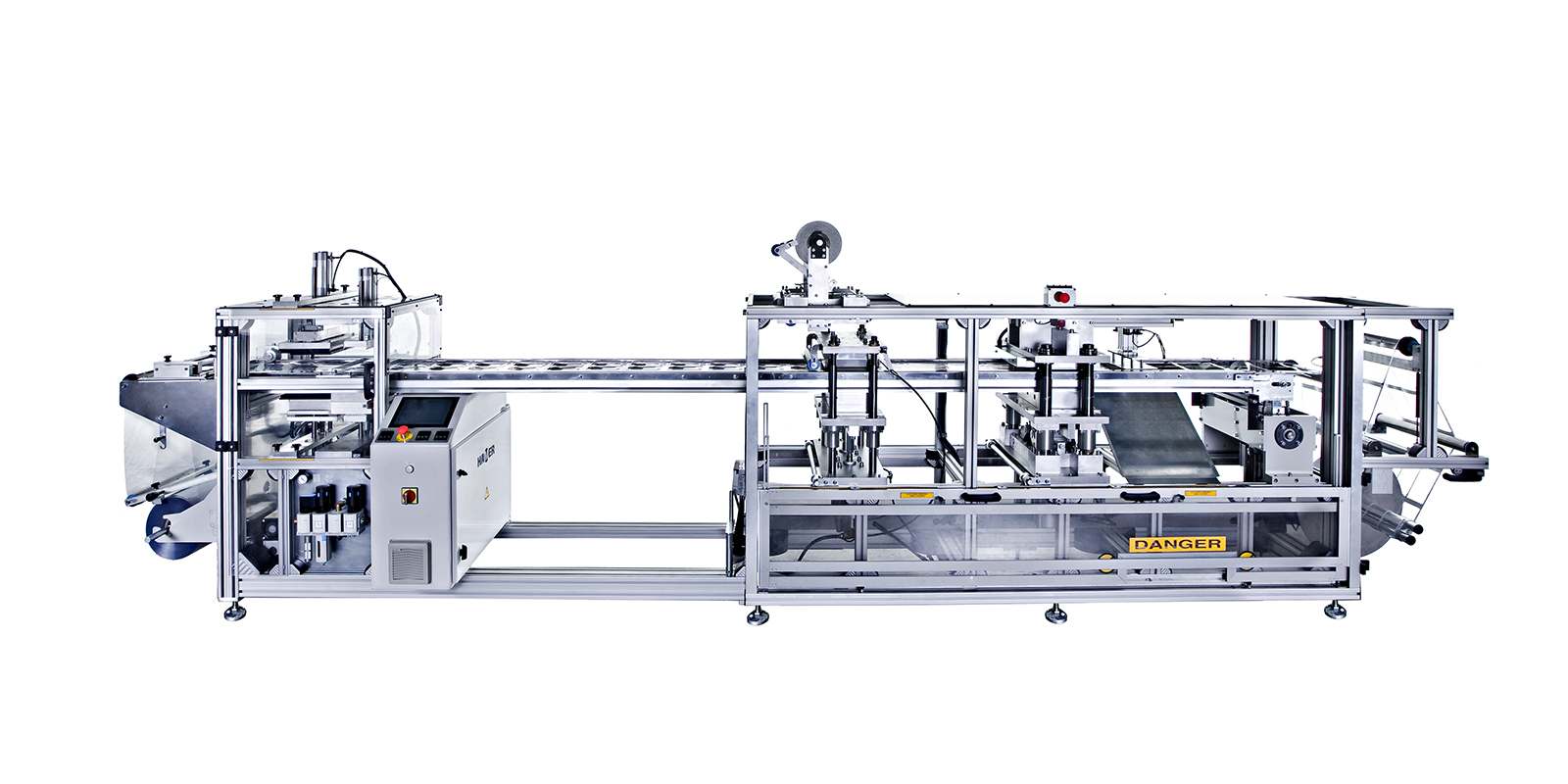

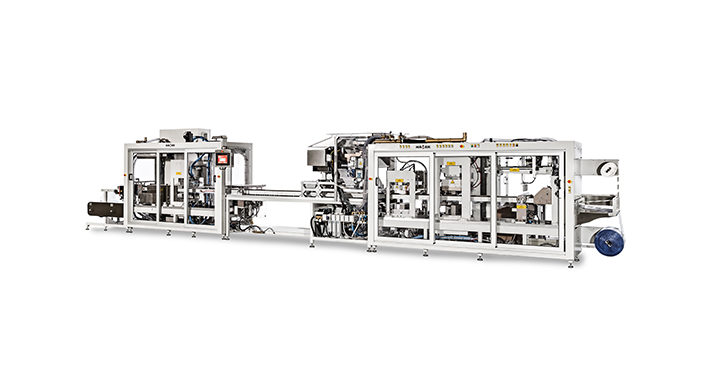

Automatic line machine suitable for manufacturing face-seal blister, full-sealed blister and full plastic blister.

Features

- Dedicated to the production of short and medium runs

- Low operating and maintenance cost.

- Quick tool set change-over, done by only one operator.

- PLC operated, touch-screen controlled.

- Steel-rule die cutter, which avoids misalignment in the cut.

- Film traction by chain conveyor.

- Monoblock chassis that does not require assembly at start-up.

- Optional automatic card feeder.

- EU safety rules compliance.

Operation

The BPC23 integrates all the necessary operations for the manufacture of the blister, from the thermoforming from a plastic roll, through the loading of the product, sealing, individual punching of each of the figures and expulsion of the finished blister.

Dimensions approx. (H x W x D)

1.500 mm x 880 mm x 5.500 mm

Estimated weight

1.400 Kg

Forming film roll diameter (max.)

400 mm

Forming film thickness (max.)

0,5 mm

Forming film width (max.)

350 mm

Forming film width (min.)

180 mm

Forming area (max.)

310 x 210 mm

Forming area (min.)

150 x 100 mm

Forming depth below film line (max.)

60 mm

Vacuum pump flow

21 m3/h

Heating power

4.8 kW

Sealing film roll diameter (max.)

300 mm

Sealing film thickness (max.)

0,15 mm

Loading area length

1000 mm

Loading area height

950 mm

Sealing force

950 Kg

Die-cutting force

10.000 Kg

Cycle speed (dry conditions)

12 cycles/min

Total installed power

13 kW

Total air consumption (at 12 cycles)

34 m3/h

Power supply

400V+T+N, 50 Hz

Described machine specifications may differ from final specifications of your ordered machine. Some of the equipment described or shown may be available only at extra cost.

Application sectors

- DIY

- Home decor

- Lighting

- Office supplies

- Consumer Electronics

- Hardware supplies

- Toys

- Cosmetics and Beauty

- Personal care

- Automotion

- Household products

- Childhood products

- Batteries