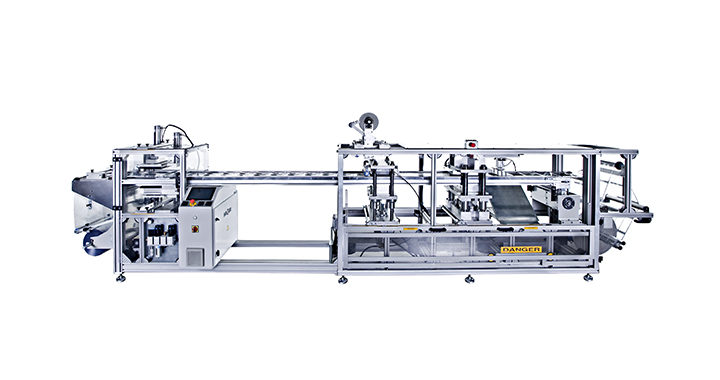

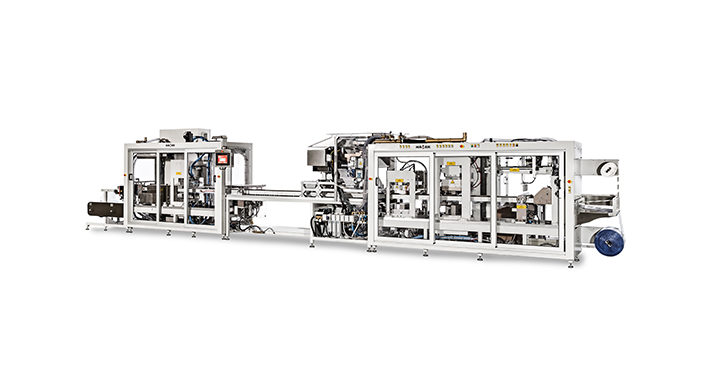

Carousel type blister heat sealing machine HC63 is suitable for the manufacturing of face-seal blisters (blister to a single backing card) or trapped blister (sealed between two cards). Blister packaging.

Features

- Dedicated to the production of medium and long runs.

- Flexible and modular design of the carousel that allows the number of stations to be expanded.

- Automatic blister feeding.

- Automatic carton feeding.

- Designed to incorporate a thermoforming station for on-line blister feeding.

- Quick change of pallets without tools.

- PLC operated, touch-screen controlled.

- EU safety rules compliance.

Operation

The HC63 carousel integrates all the necessary operations for the sealing of a blister, from bubble feed, through loading of the product, sealing and to the expulsion of the finished blister.

Dimensions approx. (H x W x D)

1.821 mm x 2.302 mm x 3.762 mm

Estimated weight

1.800 kg

Footprint

carrusel oval modular

Number of product trays

12

Seal area

600 x 320 mm

Blister height (max.)

hasta 75 mm

Pallet transport system

servo-driven

Pre-formed blister feeder station

as an option

Back card feeder station

included

Sealing station

heat sealing

Sealing press temperature range

80 to 200 °C

Sealing pressure (max.)

81 kN

Heating power 4,4

4,4 kW

Adjustable sealing pressure

included

Finished pack unloader

included

Cycle time (dry cycle)

up to 14 cycles/min

Power supply

400V + T + N, 50 Hz

Described machine specifications may differ from final specifications of your ordered machine. Some of the equipment described or shown may be available only at extra cost.

Application sectors

- DIY

- Home decor

- Lighting

- Office supplies

- Consumer Electronics

- Hardware supplies

- Toys

- Cosmetics and Beauty

- Personal care

- Automotion

- Household products

- Childhood products

- Batteries