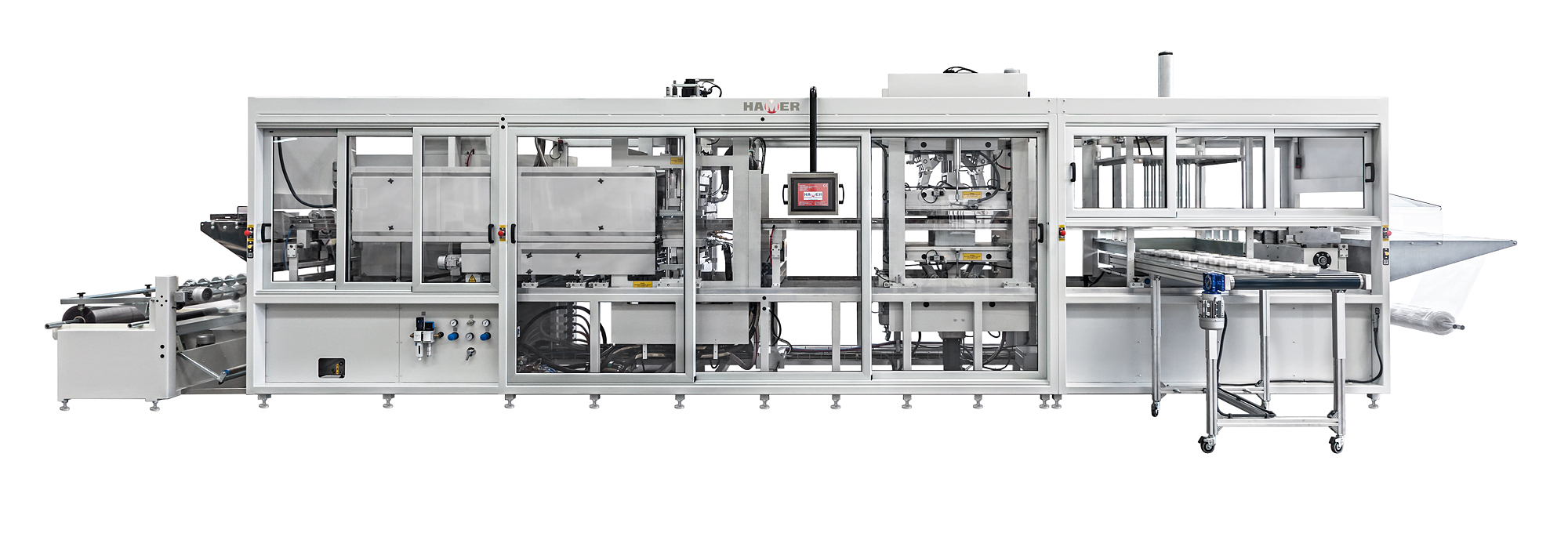

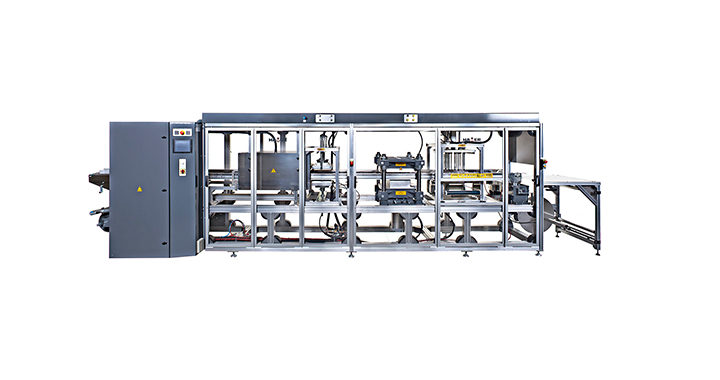

Automatic vacuum and pressure high performance thermoforming machine with separate stations for thermoforming, die-cutting and vertical stacking of the final product in a conveyor belt.

Features

- Dedicated to the production of medium and long runs.

- Big working area of 600×700 mm that allows the moulding of pieces of 140/140 mm height (above and below the film line).

- Roll feeded.

- Film traction by chain conveyor.

- Film heating (patented system).

- Fixed heater equipped with ceramic resistances and a motorized roller shutter in stainless steel that allows to regulate the area of radiation.

- It improves the initial cycle efficiency after a stop, by avoiding the overheating of the area to be molded.

- Prevents heat dissipation, reducing electrical consumption.

- Vertical stacking station “from top to bottom”

- Simplicity of stacking and adjusting tooling.

- Possibility of using the same stacking tooling for different products.

- Savings in adjustment time and tooling costs.

- Pressure forming to produce more detailed pieces.

- Servomotors driven stations that improves the quality of the part and decreases the cycle time (dry output up to 45 strokes / minute)

- It allows the installation of an additional punching station for the manufacture of special containers such as containers for fruit or blister with hanger

- PLC operated, touch-screen controlled.

- EU safety rules compliance.

Operation

The thermoforming machine is fed from a plastic roll. The film is heated in the heating module until it reaches the appropriate temperature depending on the type of plastic and then goes to the moulding station, cutting and finally, the pieces finishes in the vertical stacking station.

Dimensions approx. (H x W x D)

2.660 mm x 1.750 mm x 9.650 mm (TVP 64) - 2.660 mm x 1.750 mm x 11.850 mm (TVP 67)

Estimated weight

4.500 kg (TVP 64) - 6.500 kg (TVP 67)

TVP 64

TVP 67

Forming film roll diameter (max.)

800 mm (1200 mm as an option)

Forming film thickness (max.)

1.5 mm

Forming film width (max.)

670 mm

Forming film width (min.)

380 mm

Forming area (max.)

630 x 420 mm ( model TVP 64 )

640 x 770 mm ( model TVP 67 )

Forming area (min.)

350 x 200 mm ( model TVP 64 )

359x350 mm ( model TVP 67 )

Forming depth below film line (max.)

140 mm

Forming height above film line (max.)

140 mm

Vacuum pump flow

190 m3/h

Forming pressure

6 bars

Heating power (upper heater)

25.8 kW ( model TVP 64 )

44.1 kW ( model TVP 67 )

Heating power (lower heater)

21.5 kW

Forming tables driven by

Servomotor/Toggles

Forming tools clamping

Pneumatic clamping

Trimming tables driven by

Servomotor/Toggles

Trimming power

60 Tn.

Positioning according to index length

Motor driven

Steel rule die heating power

4 kW ( model TVP 64 )

5.6 kW ( model TVP 67 )

Transverse and angular adjustment of rule cutter

Motor drive

Steel-rule die cutting tools clamping

Pneumatic clamping

Dry cycle output

45 cycles/min

Push-out device at stacking station driven by

Servomotor

Total installed power

75.85 kW ( model TVP 64 )

100.52 kW ( model TVP 67 )

Power Supply

400V + N + T, 50Hz

Described machine specifications may differ from final specifications of your ordered machine. Some of the equipment described or shown may be available only at extra cost.

Application sectors

- DIY

- Home decor

- Lighting

- Office supplies

- Consumer Electronics

- Hardware supplies

- Toys

- Food and drinks

- Agroindustry

- Cosmetics and Beauty

- Personal care

- Automotion

- Household products

- Childhood products

- Batteries